The Guardian Monitoring System

Advanced real-time monitoring for oil well sites with comprehensive data collection and remote access capabilities.

Overview

Featuring an advanced system design, WAM enables oil companies to collect and monitor live data from various systems on the well site, with a particular current focus on closing units and Blowout Preventers (BOPs).

WAM's flexible design allows seamless connectivity to virtually any BOP or closing unit, regardless of brand or model. Its plug-and-play configuration ensures a rapid deployment, with the system delivered as a comprehensive, standalone kit. This enables swift, safe, and efficient connection to existing equipment, facilitating immediate off-site monitoring and data collection.

WAM Systems are packaged in a self-sufficient case, making it easy to integrate with on-site equipment and begin monitoring operations quickly.

Live Dashboard Interface

-

Real-Time BOP Monitoring

Live pressure readings and system status at a glance

-

Closing Unit Diagnostics

Comprehensive power unit and hydraulic system monitoring

-

Multi-Site Overview

Monitor all well sites simultaneously with instant alerts

-

Mobile & Remote Access

Access critical data from anywhere, anytime

How it works

WAM Systems will be delivered to the site by a trained WAM service professional, who will oversee the unboxing and installation process. The system begins with the setup of a color-coded electrical connection panel at the BOP, where pressure transducers and proximity switches will be installed on the BOP and inline of the closing unit hydraulic hoses. These components monitor pressure and track the opening and closing of the pipe rams on the BOP. A single line, running parallel to the hydraulic lines from the closing unit, will then connect back to the base case of the WAM system. In addition to monitoring BOP functions, WAM will continuously track various parameters, including accumulator pressure, manifold pressure, annular pressure, and hydraulic fluid levels of the closing unit. The system also monitors the oil pressure, coolant level, fuel level, battery level, and a failed-start alarm for the power units of the closing unit.

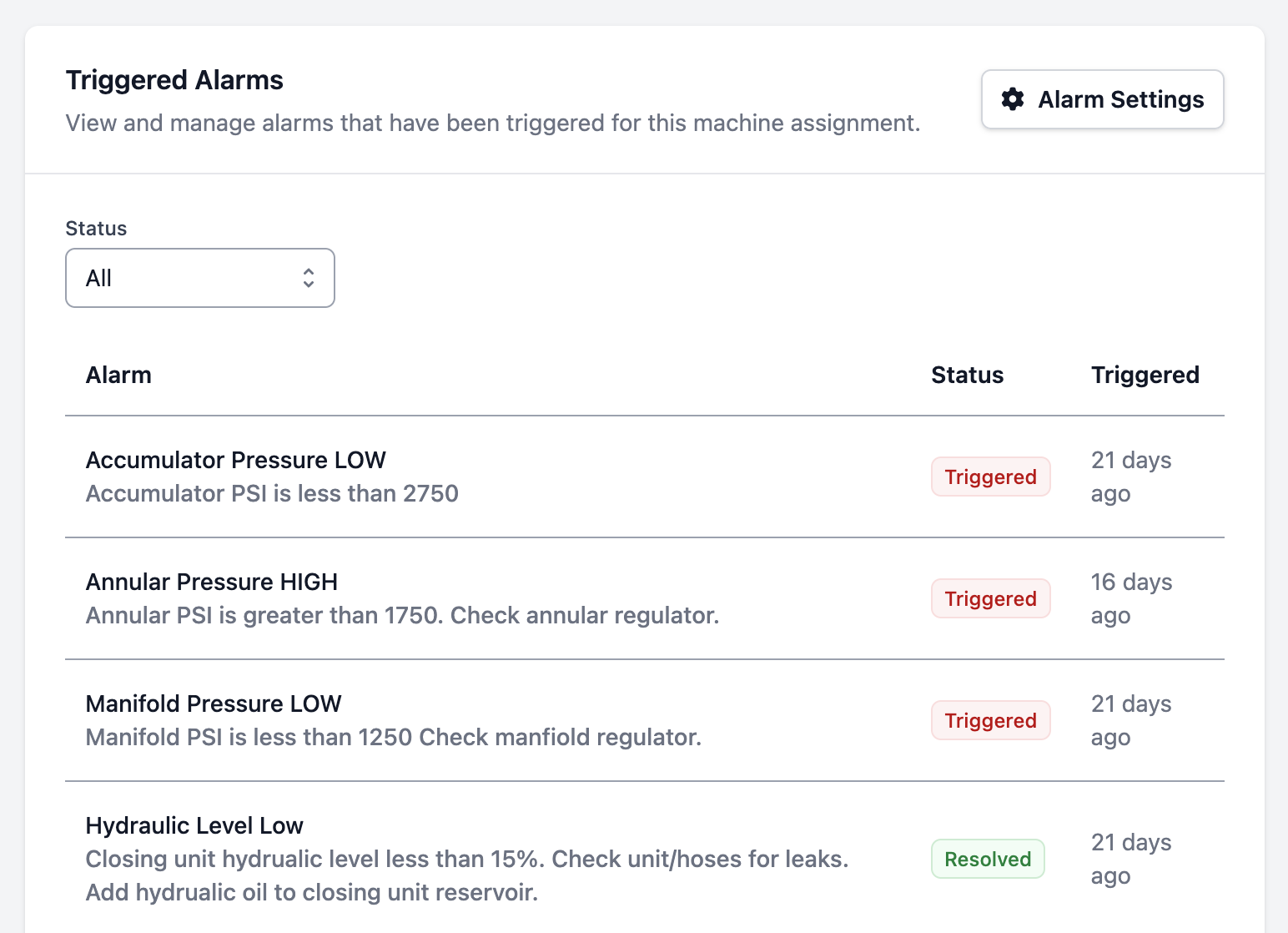

Prior to or upon arrival on-site, a company representative will input essential information into the provided tablet, including the geographical location of the well site, BOP configuration, typical operating pressures, etc. Once the system is physically installed and connected to the internet, data monitoring and collection will begin. The WAM system can be accessed via the on-site tablet provided by WAM, or remotely through a cell phone or computer. Additionally, WAM will send real-time alerts to designated personnel whenever an alarm is triggered. Notifications will continue until the system receives an acknowledgment or response. Authorized personnel can monitor multiple well sites simultaneously, ensuring that all systems operate smoothly, safely, and efficiently.

WAM’s BOP and closing unit configuration represents the first of many innovative solutions that WAM will offer to the oil industry. At WAM, we believe that WAM is the next generation of Well Asset Monitoring. Our commitment is to provide systems that alleviate the challenges faced by oil companies and service providers, ensuring that well sites operate with the highest standards of safety and efficiency. By providing immediate alarms when issues arise, WAM helps prevent downtime and supports proactive maintenance.

The data collected by WAM plays a crucial role in enabling informed decisions related to safety, operational efficiency, and long-term performance. This technology marks a significant step forward in the evolution of oil production asset monitoring, empowering companies to optimize their operations and enhance overall productivity.